3D-Printing consists in melting plastic at ~200°C inside the "extruder block". The materials used are : mainly PLA, ABS, PETG, and many more like Nylon or Carbon Fiber based. I strongly recommend PLA because it's organic.

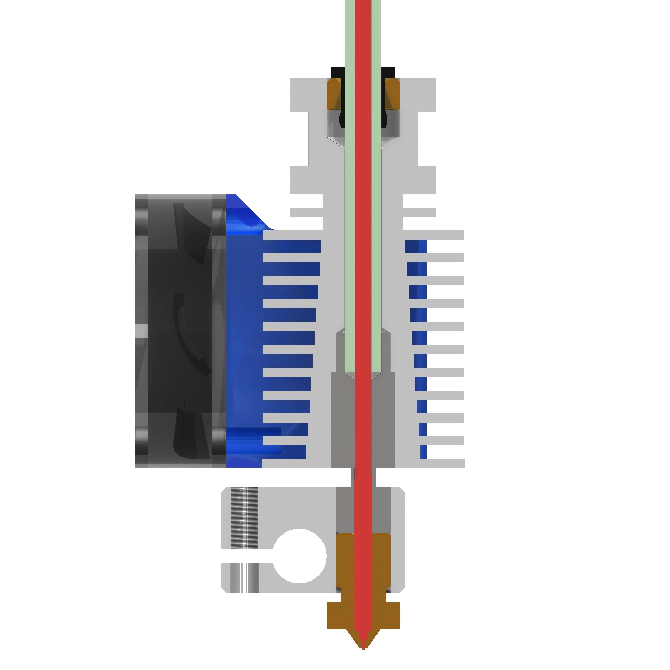

In the following half section view of the extruder block : in red, the material is compressed down to the 200ºC extruder area.

The aluminium wings -in grey color- isolate the rest of the 3D-printer from the high temperatures achieved with a ceramic isolated heating Resistor inserted in a cylindric hole at the bottom of the extruder block, near the plastic output, measuring 0.4mm.

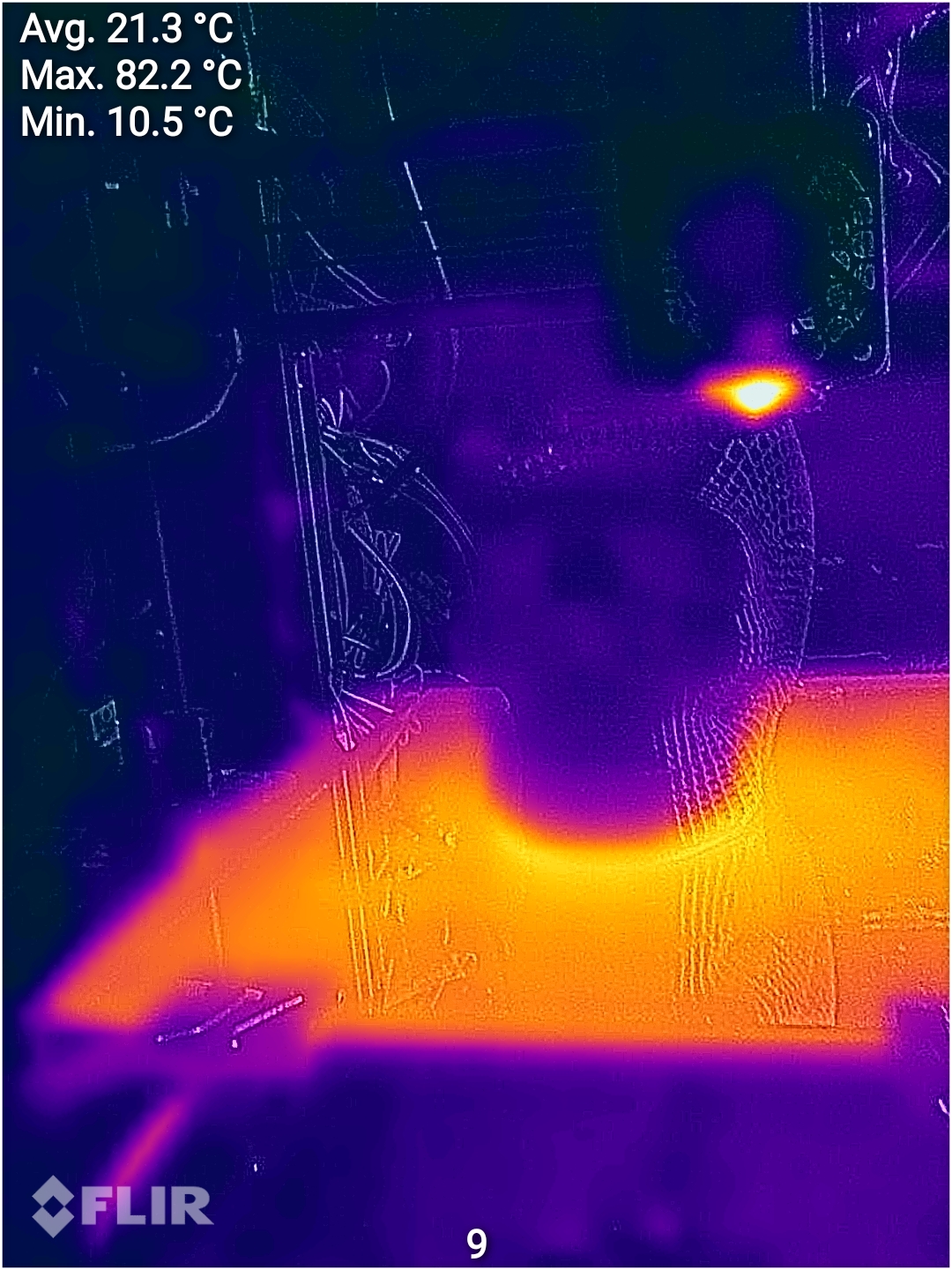

Here you can see that the glass under the object is warmed up at 60°C. The extruder is at ~200°C inside and is isolated from outside with a special rubber so it only shows 82.2°C (in white above the object).

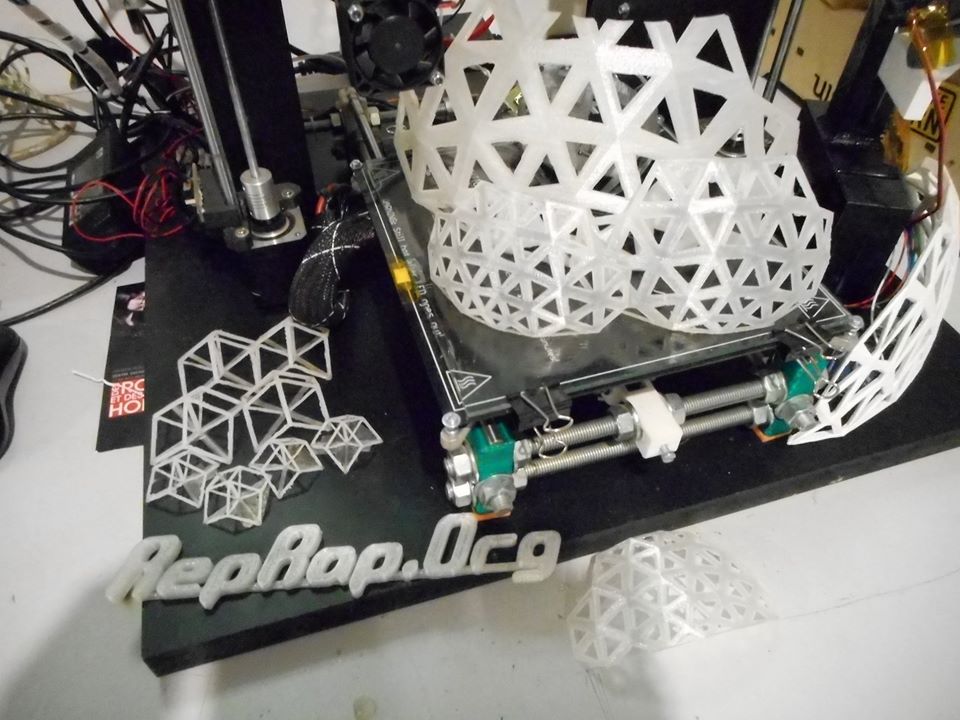

The extruder is moved on the X axis, while the object moves on the Y axis (on this particular machine called RepRap Prusa i3 reWork) to deposit the melted plastic layer by layer, starting from the glass at 0.2mm per layer with a 0.4mm extruder diameter. This is customizable : extruders are from 0.1mm to 1mm, layer height must be between 0.1mm to ~0.85mm depending on the extruder hole diameter, so YES precision is important, but quite easy to achieve in fact, with good components.

When each layer is completed, the extruder is raised on Z axis, by the "layer height" amount of mm.

I have two powerfull wind turbines blowing fresh air on the object, which I started to use right from the start by instinct : two fixed and powerfull fans are better than having a small fan on the extruder itself adding weight on a mobile (and important) part: the extruder.

I saw my first RepRap in Paris at the /tmp/lab then I built mine at the end of 2012. Starting exactly in January 2013 to 3D-print on my own "RepRap Mendel".

Then I upgraded, a unique thing with this hardware, to a new version : the RepRap Prusa i3 ReWork from the french company Emotion-tech who I know from the begining of their adventure ! Thanks to them for their support.

You can find more informations all around Internet like :

Wikipedia Definition of 3D-Printing

There's a lot of websites about it. See the /LINKS page.

Here a last example of a Pan-Tilt machine I made in 2016 for a party organizator, it can carry 2,5Kg of hardware oriented on 2 axis, controlled by a simple arduino Uno and a motor shield. The HeavyMeta Pan-Tilt was originally made to carry a video projector, but I tried it with a Kinect v1 3D scanner on the picture bellow :